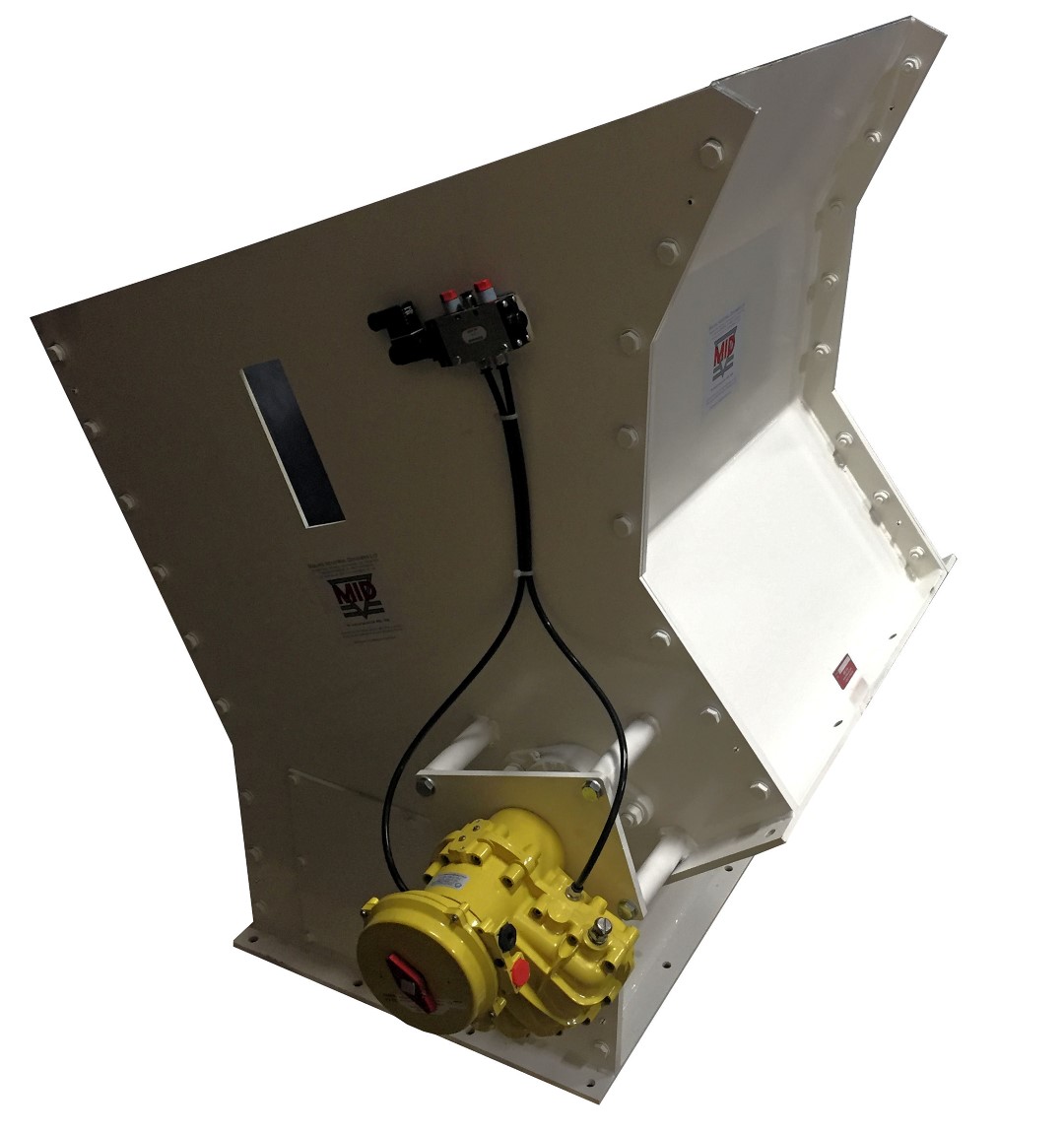

Custom reject diverter

A global gypsum manufacturer needed a custom made reject diverter for their scrap inlet line.

The feed conveyor is fitted with a magnetic detector. The existing system stopped the conveyor and relied on someone to remove the tramp material from the conveyor with a child’s toy rake! We were asked to carefully survey the existing installation to provide a unit that could reroute the contaminated material without interrupting the process.

Afer some careful measuring, we used a modified version of our GR fabricated gravity diverter- it even had the holes cut out for the belt scraper unit.