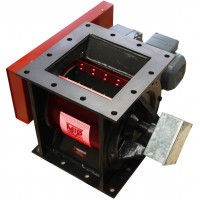

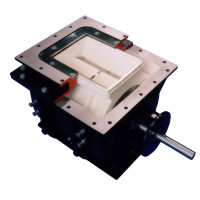

Description

The tiles we use are not glazed but hard all the way through. They’re 92% alumina which is resistant to all but the very hardest of materials- diamond.

An option on the TWA units, the ceramic parts are designed to be repaired an unlimited number of times- we remove the worn out tiles, repair any damage to the body of the valve, replace the tiles with new and regrind them.

All of the TWA units are supplied with our unique maintenance free mechanical shaft seals giving unrivalled longevity and no maintenance for critical, high wear applications such as the conveying of sandy alumina or other very hard materials usually unsuited to pneumatic conveying.

Wear resistance

![]()