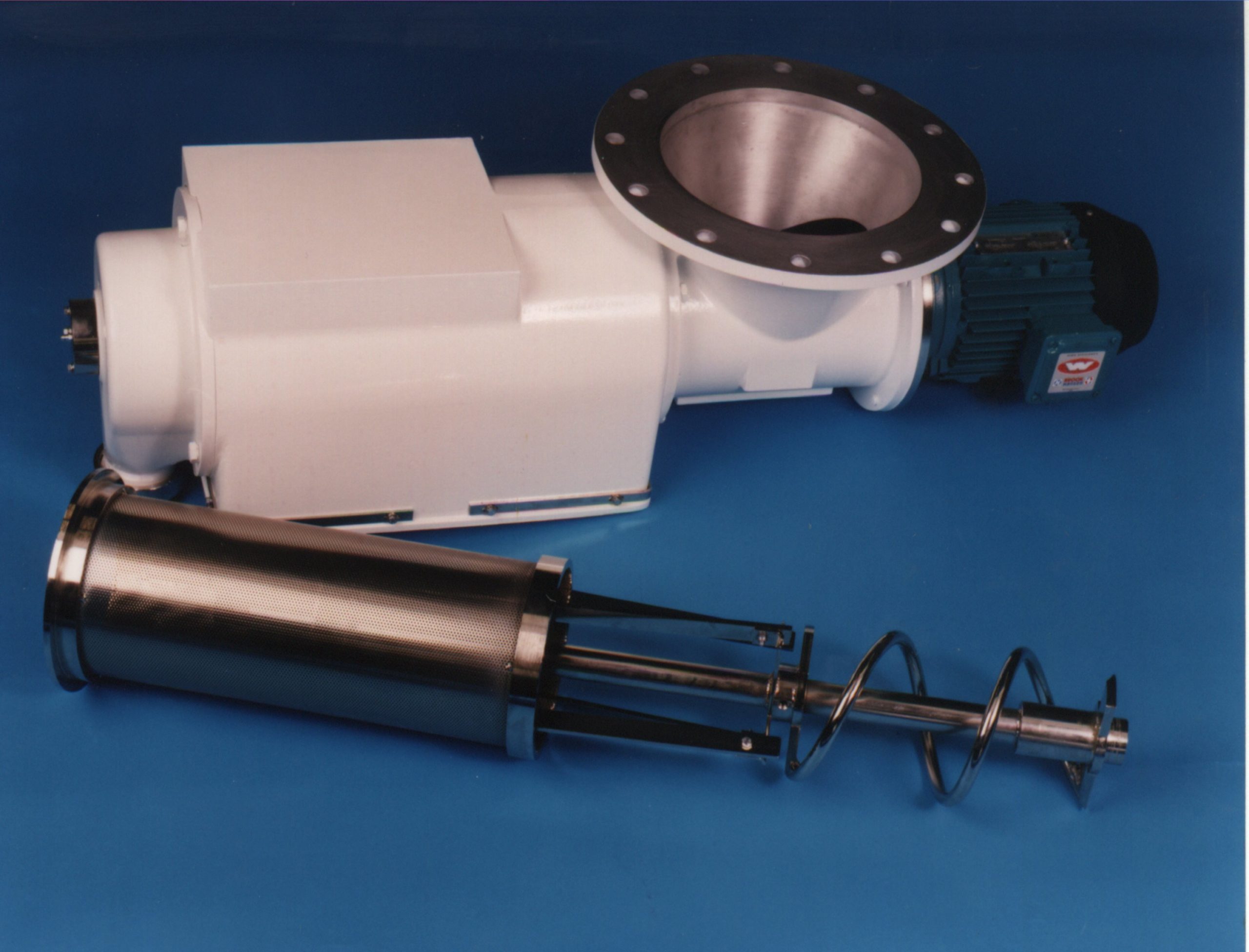

Description

They can be supplied with a number of options, including:

- different screen sizes

- wedge wire screen

- aluminium or stainless body

- inlet swivel for feeding multiple mixers

- outlet dust suppressing skirt

- inspection panels

- quick removable rotor

- fan assisted filter vent unit

- inlet cyclone

- pneumatic conveying version- sift “inline”

- condition monitoring equipment

- ATEX certification