Cement sector valve

MID’s product line is not limited to standard valves or variations on standard- we manufacture one-off designs for customers on a regular basis.

Cemex Rugby plant needed a replacement for their main silo outloading valves that feed the cement tankers you see driving around the country delivering their product.

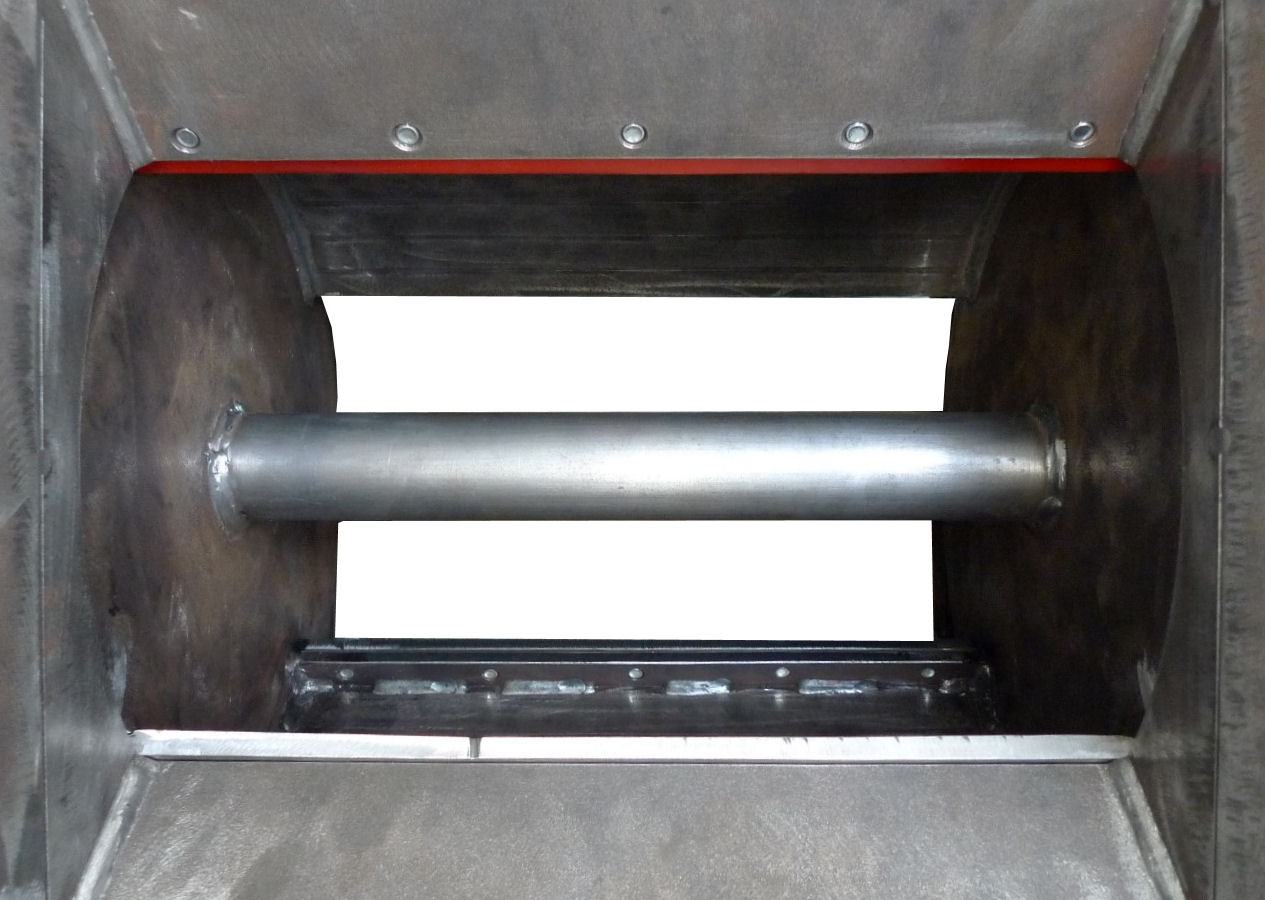

The existing units were a little agricultural- bent steel thin section plate, big unmachined gaps and rubber seals that wore away leading to cement flushing through the valve and into the airslide where it would need to be manually cleared, an expensive and annoying operation.

We have designed a custom valve using our expertise in facbrication and machining. The valve uses hard 400 Brinell wear plate, carefully machined to give only a 0.5mm gap between the body and rotor. The body inlet has a clever return designed into it so even if the cement gets through the gap, it meets a vertical wall so can progress no further.

Actuation is from a reliable Kinetrol actuator with spring return unit with only 1 moving part and no complex linkage to wear. The valve is expected to last many thousands of operations with no maintenance and is designed to be refurbished when worn to give many years service life.