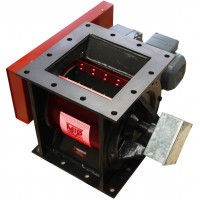

Description

Breaking news

The TWA is now available with a 1000mm rotor with a 640 litre/rev capacity.

—

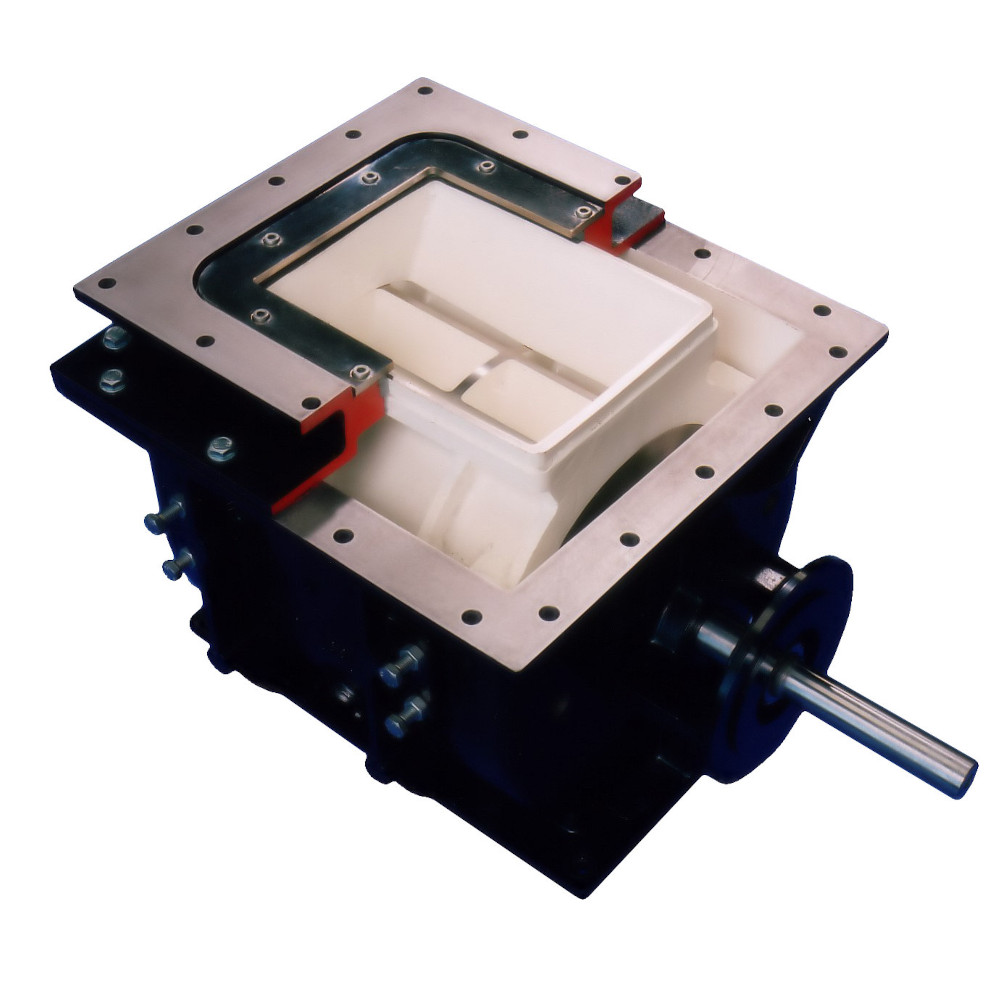

The standard unit comes equipped with:

- Ni-hard rotor

- Ni-hard adjustable liner

- Mechanical, leak and maintenance free shaft seals

- Adjustable clearances

- Outrigged bearings

- Direct drive

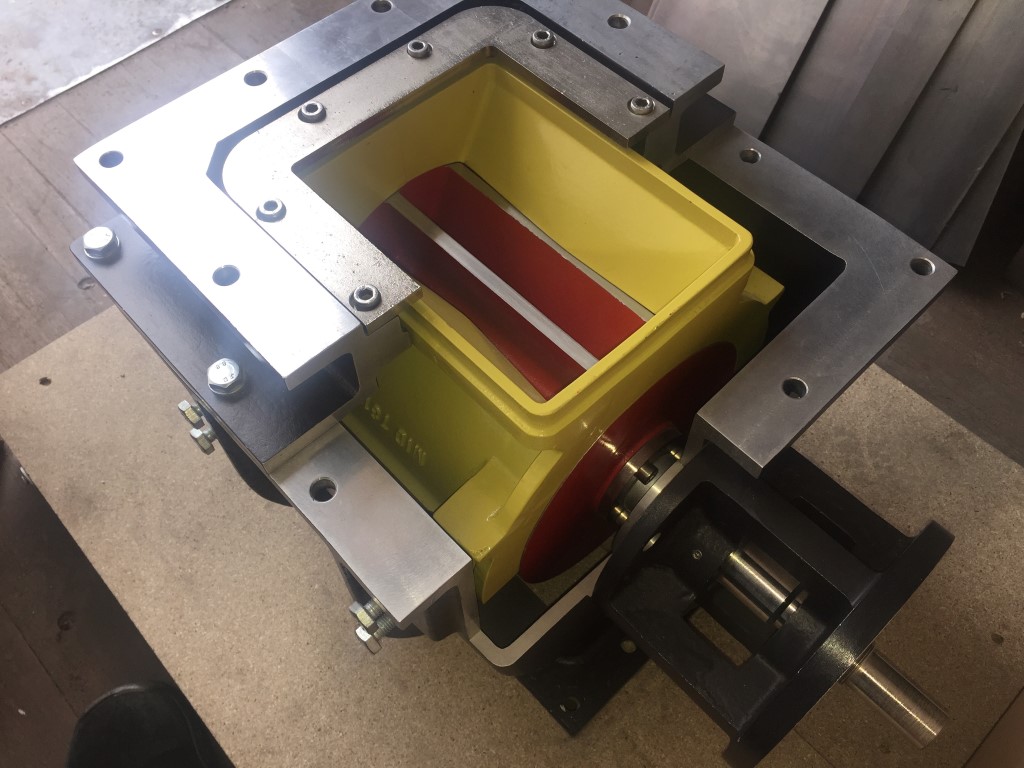

Ni-hard, unlike a thin wear coating, is hard all the way through, will not flake or pit and is very strong.

However a rotary valve is only as strong as its weakest point- usually the shaft seals. The TWA pioneered the use of mechanical shaft seals and they last as long (if not longer) as the service life of the valve without adjustment, lubrication or maintenance.

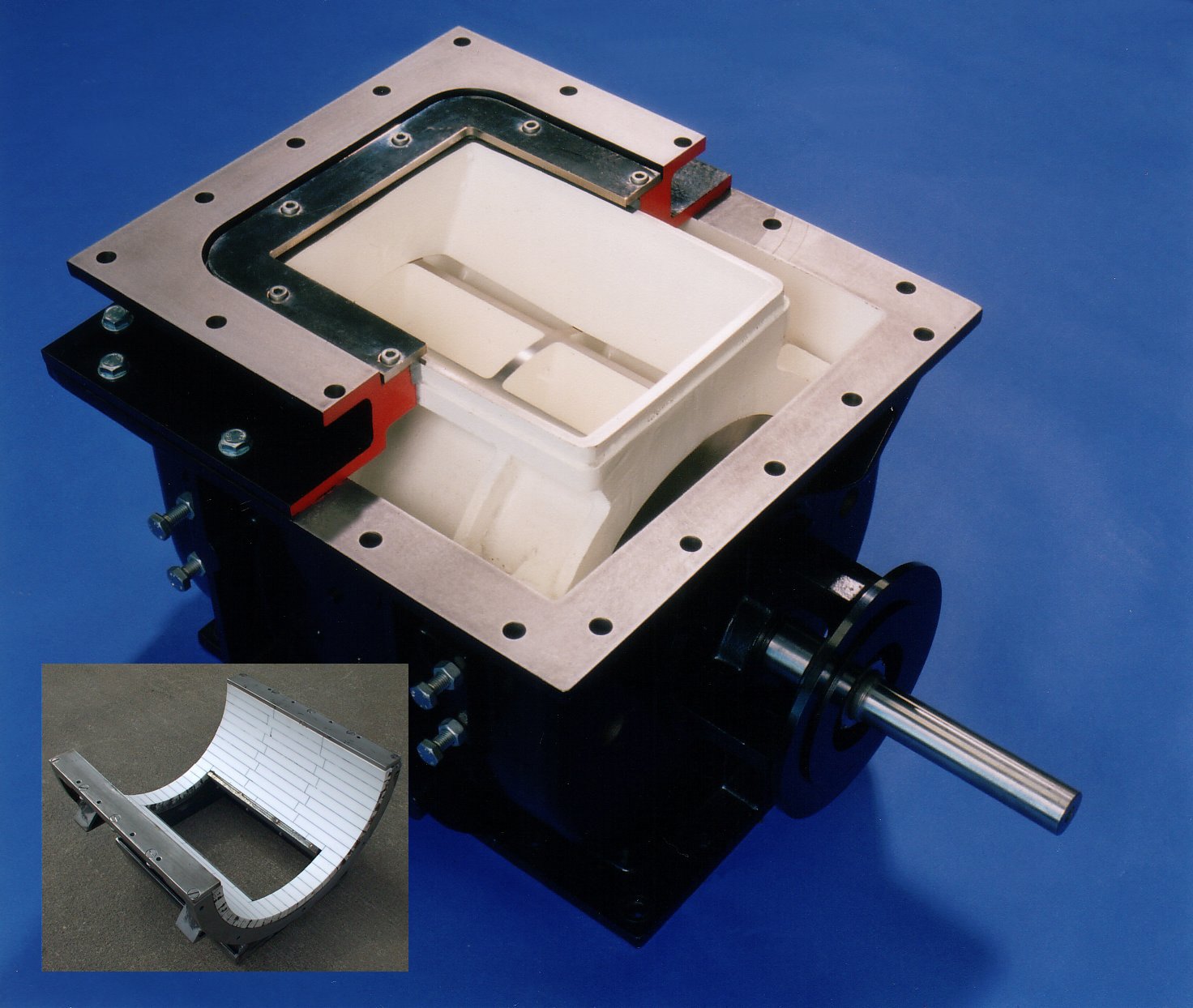

When eventually the valve does wear, the rotor can be reground and a new, undersize liner fitted at the fraction of the cost of even a new “standard” rotary valve. The valve is returned “as new” and will give the same service life as a brand new unit.

The TWA is the most economic long-term valve available and the payback on these valves is normally extremely quick.

For the ultimate in valve longevity, the TWA can also be fitted with an alumina ceramic tiled rotor and liner.

Wear resistance

![]()