Ceramic valves for repair

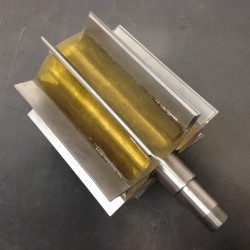

The TWA ceramic rotary valves are designed from the outset to be reconditioned to “as new” with changeable wear parts. These valves are installed under electrostatic precipitators handling fly ash at a coal powered power station run by RWE in Niederaussem, Germany. There are 36 valves and 12 spares, transferring ash from the ESP outlets into a Claudius Peters Fluidcon pneumatic conveying line. The ash is extremely abrasive as the power station burns brown coal with a high…