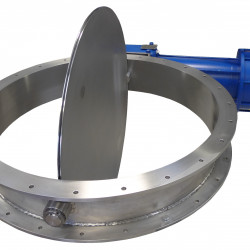

Large explosion isolation valve

Working in an exclusive collaboration with Fike, the market leader in explosion protection, we have designed and built some large 1×1.2m explosion isolation valves that are currently being tested by Ineris for Atex certification as a protective device. The valves are used as part of an explosion detection, suppression and isolation system. The challenge was to get the 135kg slide plate closed in under 300ms without destroying the valve. Fike have use computation fluid dynamics to model a…