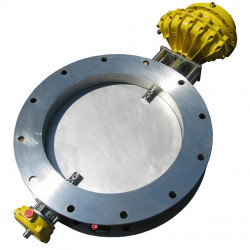

Leaking shafts

ARE YOU…………… Spending valuable time maintaining shaft seals on your rotary valves? Spending money on raw materials that end up on the floor? Wasting time and money processing materials that don’t reach the end of the process? Struggling to maintain housekeeping & health & safety standards? Looking for significant productivity improvements? Leaking rotary shaft seals are an ‘age old’ problem that Engineers have been facing for many many years and even though there are a number…