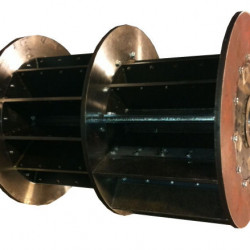

Explosion proof diverter valve

An international textiles technology company approached MID to help with the bespoke design of a diverter valve with 450mm inlet/outlet, that could withstand an explosion pressure of 10 bar. Traditional diverter valve designs would not cope with this sudden increase in pressure – at best the panels used to construct the valve would just buckle and at worst they could become detached from the valve creating a significant safety risk to those close by………. MID…