Minerals

Over 300 million tonnes of minerals are extracted from the UK landmass every year. The majority of this is supplied to the UK construction industry, improving our housing stock, transport networks, commercial and industrial buildings, utilities, schools and hospitals.

Over 300 million tonnes of minerals are extracted from the UK landmass every year. The majority of this is supplied to the UK construction industry, improving our housing stock, transport networks, commercial and industrial buildings, utilities, schools and hospitals.

At MID, we like minerals. They provide us with a wonderful opportunity to demonstrate how well our valves perform under the harshest of environments.

Minerals are abrasive, from the mild to the extreme, and without the right equipment in place, they can cause a variety of issues that can impact on your productivity.

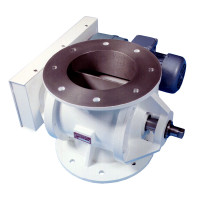

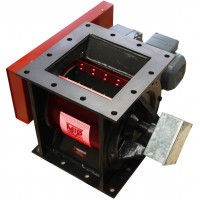

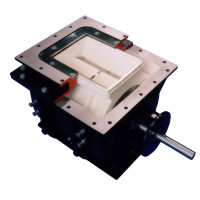

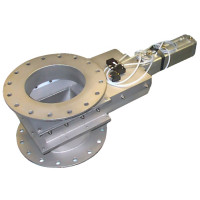

Our rotary valves are built to withstand wear and in many cases they’re completely maintenance free. Our extreme duty ceramic TWA valve really is the ultimate in wear protection. Our MVX will last up to 4X longer than a cast iron valve and can be manufactured to the same footprint as any other manufacturers valve and our mechanical seals are guaranteed not to leak and not to need regular routine maintenance. Why wouldn’t we like minerals?

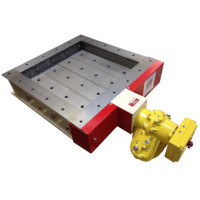

Almost every single MID valve can be modified to increase wear resistance, reduce maintenance and reduce costs, including our slides, diverters, butterfly valves and dampers.

Typically our valves handle

| Fly Ash | Slate | Granite | Limestone |

| Cement | Clinker Dust | Coal/Shale | Sand/silica |

| Dolomite | Gypsum | GGBS | Anhydrite |

Related Products

-

Atex Rotary Valves

-

MV Rotary Valves

-

MVX wear resistant

-

MVF made to fit

-

TWA Extreme Duty Rotary Valve

-

Ceramic Lined

-

Custom Valves

-

Quick Clean

-

Self-cleaning

-

Offset

-

RBS/X Blowing Seal

-

SR Straight Drop

-

Overhaul and Repairs

-

Louvre Valves

-

Barrel Flow Control Valve

-

FSV Fabricated

-

Knifegate Valves

-

TESV Totally Enclosed

-

Cement Valve

-

GR Gravity

-

TSY Conveying Diverter

-

BV Flanged

-

WBV Wafer

-

Mechanical Seals